The Wind Waggon team arm wrestled for several days before a glimmer of a game plan began to appear. During that period Mr. Smellows bore the brunt of Mr. Kellies impatience. Mr. Kellies, the Master Waggon Works owner and general manager, would holler at Smellows when he did not see parts being made or assemblies being put together. Mr Smellows shielded the bulk of the team from Kellies' wrath and pushed the master workers to work faster and harder. He knew from experience designing and building other waggons that Mr. Kellies wanted the wind waggon project tp happen quickly, much quicker than was actually happening. He also knew that the wind waggon was by far the most complicated venture yet undertaken by Master Waggon Works.

The wind waggon team was having many problems; key details were not obvious making design details hard to come by. The team did not want to begin making parts until they had a suitable design. They came to realize that the most urgent task was to create a good concept for the sail panel turntable and firm up how that would be built. Unfortunately, when they discussed their views with Mr. Smellows they did not get any useful suggestions from him or firm decisions among alternative ideas they presented to him.

Once the turntable design priority was established the master wood-worker Ekelis Santzit and master machine worker Artia Yousote (Danikels boss) began to draw up several sketches of possible turntable concepts. Those ideas would need more detailed discussion by the wood and machine works teams as to how they would be made and various details for the various pieces.

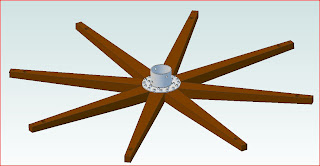

The turntable mounting method would dictate how the middle portion of the waggon would be configured. Support structures for the turntable would be located in that mid section. A paddle wheel and axle mounted vertical passing through the roof of the waggon was the general idea that all agreed upon. The paddle wheel would be the turntable structure above the roof with the axle passing from the top of the turntable through the bottom of the floor inside the waggon. The paddle wheel would be made up of two support wheels, one at the bottom of the paddles just above the roof and the other at the top of the overall paddle wheel. Between the support wheels would be the paddles composed of sail panels. The turntable structure would be mounted on bearings at the roof and floor of the waggon.

The wood workers and the machine workers were at odds about ways of joining key parts that would make up the turntable. In particular the method of joining the sail support arms at a center hub was proving to be a struggle. Artia the master machine worker and Ekelis the master wood worker had opposing views of how to make the basic turntable wheel structures. Both did agree the radial sail support arms would be wood beams. They disagreed how to join the wood beams at the center hub.

Ekelis favoring a solution that used proven waggon methods of joining the arms in the way spokes of wheels were joined at the center and rim. That method would need a large force to push the large wood arms into a very large wooden center hub. It was not clear that such a large hub could be made. Hubs were made from a single piece of wood shaped from the lowest part of the trunk of a tree. A very large hub would require a very old, very large tree. There were few trees of such a size, perhaps none existed.

Artia on the other hand favored using a smaller metal hub. Each wood arm would then be connected to the hub with bolts. Ekelis did not have a good feeling about the smaller metal hub as waggon wheels still were made with wood. Artia had a good feeling about a metal hub. Metal parts of similar size were now being made successfully.

Despite his misgivings, Ekelis gradually came around to Artia's view and began to accept that perhaps the hub should be made of metal. He knew that more waggon parts were being made of metal because of it's strength and durability despite the higher cost. He also had the gnawing feeling that it would be extremely difficult to find a large enough tree trunk to make the hub.

Turntable support wheel concept with metal hub and wood beams

The first somewhat firm concept shown to Smellows is the wood beam arms of the support wheel joined by a metal hub. One support wheel would be at the bottom of the turntable paddle wheel structure and a second at the top. Each of the eight wood beams are shaped so they would join near the middle by the hub. Each arm would have holes drilled so that bolts would connect to a metal hub at the center. Further, holes would be located towards the end for the sail panel bearings. Holes at the very end would connect to cross braces attached from end to end of adjacent arms forming a wheel.

Each beam would be made of red oak tree trunk shaped using existing woodworking methods and tools. The hub would be configured to fit the holes in a disc around a center tube. The tube would hold the paddle wheel turntable axle. Later a hub would be attached to the bottom support wheel to go down through the waggon roof and connect to the drive pulley.

When sketches were shown to Mr. Smellows he said that the concept was interesting and novel and might work. However he failed to give a definite approval. Instead he asked the master workers, Artial and Elelis, to continue work on the concept and get more details. They left the meeting with less than solid approval. They needed to push their team mates vigorously as Smellows demanded they complete their turntable work within just a few more days.

Danikel Groot and the other apprentices on the team, Burgois Loketia, Alfire Grantz, Penchist Wasterma were often quizzed by their respective masters. Why were certain details given precedence and why some possible concepts were dismissed? This was done as a learning experience so the apprentices would learn. Occasionally the masters would give an apprentice a task to draw sketches of concepts or perform computations to determine dimensions or loads.. When an apprentice did a task his master and the other apprentices would go over the work to detect errors. This process also was to further knowledge and apprentice understanding.

The most trying part of the design efforts for the turntable work was the ripple effect of changes that came about. Changes were often caused when computations or sketch details showed problems. The work on the wood radial arm beams was done mainly by the woodworkers while Danikel, his master and the two other machine workers prepared the hub design they were responsible for.

Eventually details of the wood radial beams was frozen along with the hub. Then the remaining parts of the turntable could now be sized and added to the sketches. One element was the need to connect the outer ends of the turntable radial arms to form a wheel. Once again the arguments flowed back and forth whether to use wood or metal. Both were possible and would work.

Ekelis wanted them to be wood so his team would have wood work to do. Similarly Artia wanted them to be metal, mainly because they would be simple to make and would be stronger than wood for a given size. Metal braces would actually be lighter and smaller than wood pieces of suitable strength. Fortunately the choice became fairly obvious that the arm to arm braces at the ends should be metal. A single bolt at the end of each radial arm would hold the two side braces in place at each end. Attachment of metal braces was simpler than what would be required to hold wood braces in place.

Turntable concept with metal arm braces

There was no argument with Artia concerning the need for the sail panel paddle bearings to be metal to mate with metal shafts at each end of the sail panel.

Mr Smellows would come by daily and look over sketches and computations. Every couple of days he would ask the masters to his work bench area and discuss further how their work fit the overall wagon concept and various details to better understand how the parts were to go together.

It took several weeks to get to the above design concept for the support wheels. Mr. Smellows wanted the parts nailed down so that he could order the timber from a wood supplier and begin work shaping the parts. The hub and tip brace metal parts must also be ordered from a metal works. Both types of parts would in turn be finished at Master Waggon Works by drilling holes, trimming parts to final shape and other details.

Turntable concept with metal bearings for sail panels

The teams now had enough detail to determine the weight and sizes of the turntable support wheels and their parts. They had worked through an entire week with late night and weekend work and now had a reasonable concept to present to Mr. Smellows. Once again Mr. Smellows did not give solid approval. He commented that perhaps this might work, he would think about it and give his opinion later. He pressed Artia and Ekelis to work harder and develop details of the sail panels and central shaft for the turntable paddle wheel. Once again he pressed the team to work quickly and now begin to make parts so he could get Mr. Kellies off his back.

The team masters knew that what the work teams had sketched would be about as good as they could get. They went back to the work area and hinted that the design was acceptable and now they needed to work on the sail panels.

The remaining details of the sail panel bearings, sail panel rotation limit blocks would be done later. The team had also realized that design of the sail panels was also a priority so that bearings and rotation blocks can be designed.

Meanwhile, Ekelis and his team fashioned an example of the wood radial arm beam from a hard wood tree. The part was carefully measured and cut using the large water powered saw. It took several days to accomplish the job. The holes were drilled as well so the whole team could see the result.

Example Radial Arm Beam Built By Ekelis Wood Working Team

The beam was moderately heavy, weighing at one and one fifth man-weight (about 200 pounds). A man-weight was established on a balance scale at the waggon works as the average of some twenty workers many years ago. Large stones of various sizes were then carved to provide a reference for one, one-half, one-quarter and one-eighth man-weight. Subsequent to that long ago effort, balance scales had been developed that provided a ready means to weigh various parts or assemblies built at the works.Since the overall turntable mechanism would require sixteen such beams the weight of those alone would be seventeen man-weight (about 2880 pounds). Such a mechanism would indeed be very heavy and massive considering that other parts would be added as well. A further concern is that half of the beams would be at the top of the turntable assembly.

That would put about eight and one-half man weight of heavy wood beams some five and four tenths man-spans (32.5 feet) above the waggon turntable deck. The waggon deck itself is expected to be one and one-half man-spans above the ground putting the heavy top load very high above the support of the wheels. Such an arrangement would tend to tip the waggon over more easily on slanted ground.

A waggon to carry such a huge weight would be very large, perhaps bigger than was being contemplated. The entire team was surprised over the weight. After much talk and pressure from Mr. Smellows the team worked to reduce beam weight. Calculations were re-examined for the various parts of the sail panels and some weight reductions were made. The team also agreed that the radial arm beams need not need as much strength as had been originally selected.

A revised beam was designed and again Ekelis' team carved a suitable hardwood log to the new smaller shape. It was just as long at two and one-third man-span (about 72"). The reduced size was more difficult to make requiring angled cuts on three sides rather than just two as was used for the first design. The new lighter radial arm was weighed as well and found to be slightly over two-thirds man-weight (about 100 pounds).

Second Lighter Weight Radial Arm Example

Although the weight was about half of the first example, the team was concerned that the overall weight of the turntable assembly would still be too much for the waggon structure being developed. Ekelis' team included one man who had experience at another company building wind-mill arms and water wheels. He pointed out that those items were built from smaller boards nailed, screwed or glued together in lattice structures. Those were fairly light for their large size. Elelis went and explained to Mr. Smellows and other team leaders that concept.

During the discussion Artia pointed out that structures built from metal could be much thinner and therefore lighter than wood structures. Lattice structures of metal were being built for lifting machines. Such long movable machines could not be made of wood. Wood lifting machines had to be made in stacked sections and assembled on-site because of their weight and being too flimsy to move once assembled. Artia wanted to build an example radial arm of metal to see if it would be lighter. He requested that Mr. Smellows let Artia's team design a build a metal arm example that would be about the same strength as the second wood beam.

Mr. Smellows was not sure that metal would be the right answer due to the need to buy the parts from other companies. The Waggon Works owned considerable amounts of forest land and had available low cost wood. Metal on the other hand was made in metal works in other settlements. It needed to be mined and processed at other locations. As a result metal parts would be more expensive than wood beams.

Artia persisted with his idea and pressed Mr. Smellows to consider at least building an example to see if metal arms would be much lighter. If they were than perhaps the heavy wood masts in the sail panels and the central mast could also be made lighter in metal. Mr. Smellows was also concerned that metal parts would eliminate much wood work for Ekelis' crew and they would have so much less to do being idle much of the time. That might increase costs further.

Artia argued that Ekelis' team could help assemble metal structures with bolts and rivets which was a technique that did not require long training for those workers doing that job. Therefore Ekelis' team would help with metal assembly work and be gainfully occupied. Artia would not need additional team members to help with the assembly work.

Mr. Smellows and the team leaders talked about Artia's idea for a couple of days. After that time they finally agreed that Artia's team could go ahead and buy metal parts to build an example of a metal radial arm example so it could be checked out for possible use in the turntable design. Mr. Smellows also asked Ekelis and his team to examine the feasibility of building an arm using boards instead of a single log. The extra work of building two alternates to the carved log for the radial arms might pay off in more weight reduction. Either way the workload would increase to build the radial arms, but it might be worth it should the weight reduce a significant amount.

Ekelis' wood working team finished their wood lattice radial arm before Artia's team was able to complete their metal lattice version. The wood version required carving three blocks, one for the hub, another for the sail limit stop mount and a third for the sail bearing and arm brace attachment point.

Ekelis' Team's Wood Lattice Radial Arm

The wood lattice radial arm weighs near 1/4 of a man-weight (near 44 pounds). The arm had sufficient strength to properly support and planned sail panel weight.

Artia's Design Effort

Danikel and the rest of Artia's metal working team had discussed many ideas to make a radial arm of metal. Various kinds of metal available includ lightweight sheet, tube and plate. Sheet is available in larger pieces while plate is available in thicker pieces that are smaller. Tube is available in various diameters and lengths including very long lengths suitable to make the masts.Ideas flew back and forth thick and fast after Artia announced that the team was to go ahead and develop some preliminary designs and make weight estimates for a complete radial arm. Weight with sufficient strength was the driving priority. Danikel favored using thin sheets forming the top, bottom and sides of a beam. Other experienced members favored designs using plate or tube. All possible designs needed to be held together with bolts to satisfy the need for maintenance by replacing parts.

Artia split the team up to prepare more detailed concept drawings of the three most popular concepts, tubes, sheets and plates. He also instructed each little group to make a weight, labor and material estimate to build one radial arm. Artia further insisted that the teams complete their work within a couple of days.

After two full days the team was assembled along with Mr. Smellows and the other team leads. Artia asked for the sketches and estimates for weight, labor and material required to build one arm. He asked first for results from Burgoris Loketia, another third class metal and machine worker.

Partial Design Using Metal Tubes

Burgoris has completed only a partial design based on using metal tubes. That version requires several machined block components to secure the ends of the tubes. The portion completed was estimated at one-fifth of a man-weight. He also estimated that the portion completed was about one-fourth of the whole arm. Burgoris estimate of arm weight is about four-fifths of a man weight (about 135 lbs). Burgoris further estimated that the labor would be about five man-weeks of effort and would cost some fifty-eight large coins.

Partial Design Using Metal Sheets

Next Artia told Danikel to report on the metal sheet concept. Danikel showed a sketch of an arm composed of four light metal sheets, one at top, bottom and each side. The sheets were bolted to small blocks on the inside at the corners between the sheets. Danikel estimated that the concept was about eight or nine-tenths complete. He further estimated that the weight of the complete arm would be about one-half man weight when complete. Danikel's estimates of labor is four man-weeks and a material cost of 38 large coins.

Partial Design Using Metal Plate

Artia next reported his own design concept using metal plates machined to form a lattice work structure. He had completed just one part, the top or bottom plate. He pointed out that the sides would be similar. The work he did was estimated to weight be about one-fifth of a man-weight. Consequently the entire assembly would be four-fifths of a man-weight. Artia estimated labor needed at five and one-half man-weeks and 29 large coins for materials.

Mr. Smellows and the other team members noted that the wood lattice radial arm was the lightest of all concepts presented and would cost mostly labor as only small screws and nails would be bought. Wood would come from the companies forest land and was only a fraction of the cost of the expensive metal. He stated that the team had done well in creating the various concepts. He selected the wood lattice work design developed by Ekelis' team for the radial arms. He also pointed out that the metal work team would need to make the necessary hub, sail bearing, radial arm braces and sail limit stop parts for the arms.

Mr. Smellows considered that the metal tubes would make better, lighter masts than solid wood ones made from tree trunks. He ordered that the team would adjust their dimensions and use the smallest size metal tubes that would safely hold the sail parts and a larger tube that would be suitable for the main central mast.

With the important decision made on how the turntable main structure would be arranged, the team could now make detailed design drawings and build parts. Once the team would begin cutting wood and metal, Mr. Kellies would be much happier and the tension between him and the team might reduce somewhat. The team hoped so, the tension and pressure had been nearly intolerable causing the team to work very long hours each day and even on the day of rest that occurs every six days.

No comments:

Post a Comment